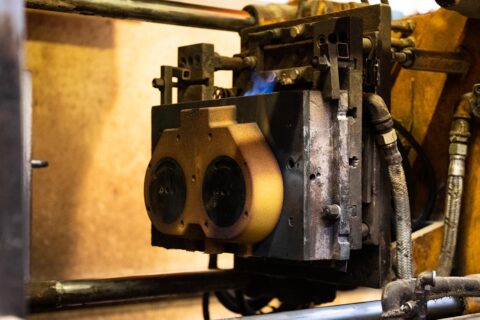

SHELL-MOULDING HOT SAND CORES

Thanks to state-of-the-art blowing machines, MDG produces shell-moulding cores designed specifically for the customer’s needs. The first phase of sand core moulding is the mixing of the raw materials with anti-crest sand, regenerated sand or pre-coated sand according to their final use. Ad hoc core boxes are made for each type of mould and installed in the machine. By injecting the sand jaw into the closed mould and heating the core case in the shell-moulding process, the raw material mixture compacts to form the core and is then extracted. Finally, the core case is cleaned in order to carry out the subsequent moulding, preventing the residues of the previous mould from generating imperfections.

MDG Srl is a manufacturer of shell-moulding hot cores.

Thanks to the experience gained over the years and the advanced technology available, we are able to offer multiple processes up to the delivery of the finished product. Our skills allow us to create sand cores that meet the specific requirements of our customers, thanks to a careful selection of high quality raw materials and the ability to mix sand, resins, hardeners and additives for every need or with the use of pre-coated sand.